The laser line polarizing cube beam splitter comes with a narrowband polarization for a higher power laser with an extinction ratio of 1000:1. When using the laser line polarizing cube beam splitters, the lasers are always moving at a single wavelength. Their dimensions are 5mm cube, 10mm cube, 15mm cube, 20mm cube, 30mm cube, 0.5” cube, 1.0” cube, 1.5” cube, 2.0” cube with their wavelength ranging from 442nm to 1550nm. These beam splitters are optimized for high-power lasers with an extinction Ratio of 1000:1 for laser line beam splitters and an extinction Ratio of 100:1 for UV laser line beam splitters. They come in cubic(cube) shape with a laser line fiber optic polarization coating but the anti-reflecting coating is done with multilayer broadband dielectric. To avoid damage, the beam should enter prism marked with a dot to give a reflected beam deviation of 90° ±5 arc min and the transmitted beam deviation ≤5 arc min. Over a clear aperture, the wavelength distortion is ≤λ/4 at 632.8 nm and operates at a temperature range of -50 to 80°C. It is Designed for Common Diode, Gas, and Solid State Lasers.

Features Of Laser Line Polarizing Cube Beam Splitters

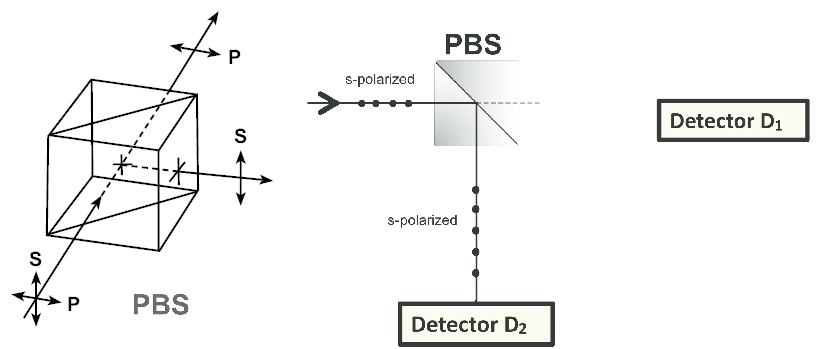

Orientation Of Laser Line Polarizing Cube Beam Splitters

In the construction of laser line polarizing cube beam splitters, two right-angled prisms are cemented together with one of the prisms having a partially reflected metal-dielectric coating applied at its hypotenuse surface. The incident light beam enters the beam more split through the hypotenuse surface which in turn helps to reduce the amount of energy passing through the beam more split cement but if the light beam enters through the uncoated part of the prism, this could lead to the beam splitter cement degradation.

Construction Of Laser Line Polarizing Cube Beam Splitters

Principally, the construction of a laser line polarizing cube beam splitters consists primarily of the assembling of two right-angled prisms. This procedure involves cementing two right-angled prisms carefully for them to be optically contacted to help reduce wavefront distortion. The four faces are coated with an anti-reflection coating which involves the use of a multilayer dielectric coating to minimize surface reflection losses but one of the surfaces of the prism(the hypotenuse part of the prism) is coated with a dielectric multilayer polarizing beamsplitter coating optimized for the laser lines. At Alpine research optics, you will get the best device for cleaning optical mirrors.

Polarization And Extinction Ratio Of Laser Line Polarizing Cube Beam Splitters

Laser line polarizing cube beam splitters have a high polarization extinction ratio. When an unpolarized light beam hits this beam more split, it splits into two orthogonal, linearly polarized components, the p-polarized light beam, and the s-polarized light beam. The P-polarized light is transmitted, while s-polarized light is reflected, both with negligible absorption rate. It has an extinction ratio of about 1000:1 for laser line beam splitters and 100:1 for UV laser line beam splitters. These cubes are recommended for use in pulsed laser systems and for purifying polarization in multimode, high-power lasers. Multilayer laser line coatings are offered for 13 laser wavelengths. They are recommended for pulsed laser systems and for purifying the polarization state of multimode lasers. They are also optimized for high-power lasers.

Multi Laser Line Coating Of Laser Line Polarizing Cube Beam Splitters

13 laser wavelengths have a multi Laser line coating.