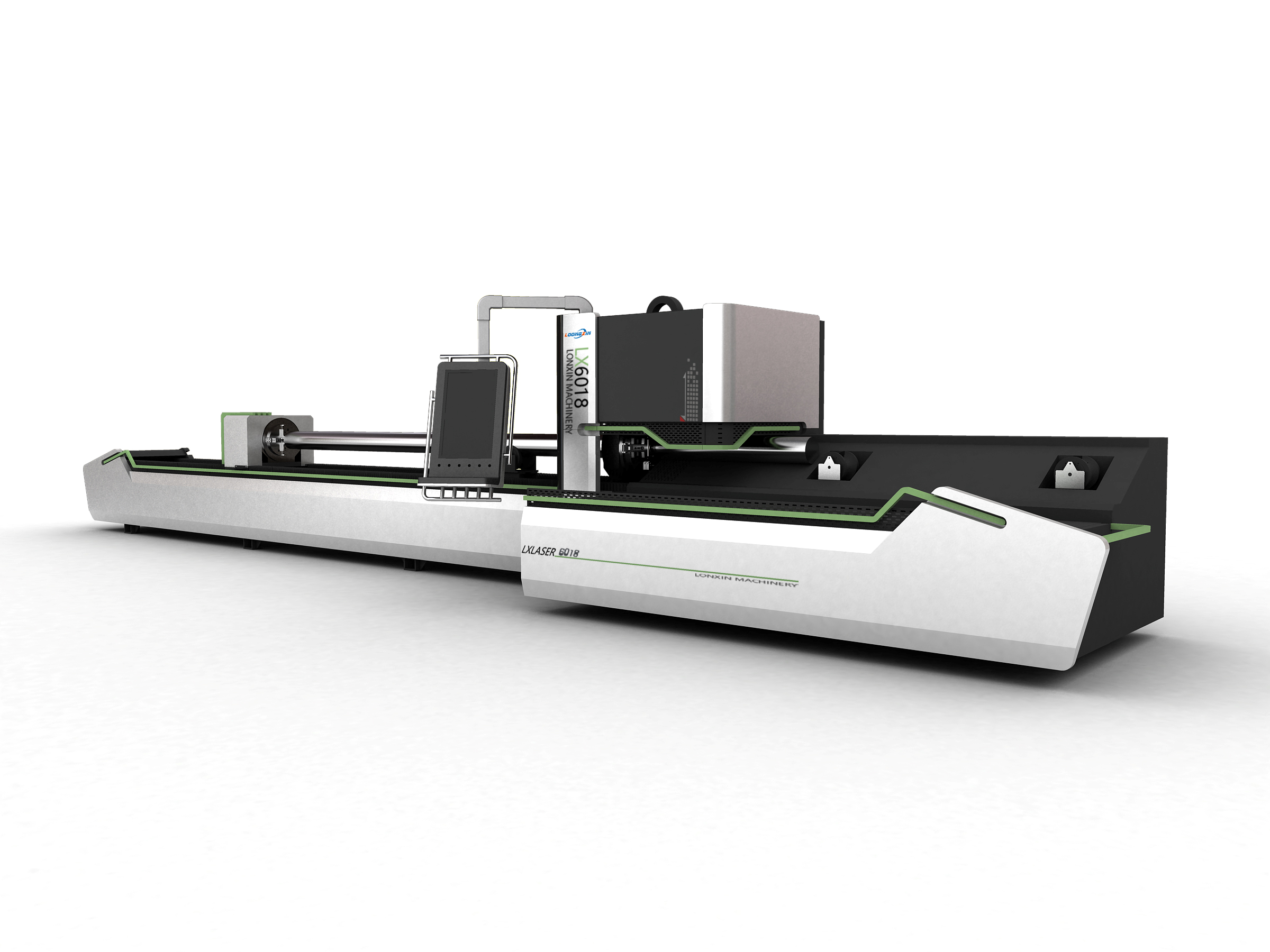

Laser cutting is a cutting-edge technique utilized by a wide range of metal manufacturing companies. Fabricators utilize a variety of processes to cut metal, but Fibre laser machine Malaysia is the most advanced of all. Fabricators like laser cutters because they can make precise cuts at a speed that other methods cannot match up to. Here is why you must use the laser cutting process for the sheet metal fabrication process

Competitive pricing

The machine cost, operation, and labor charges dictate the cost of the laser cutting task. If you compare this to hand-operated machinery, you will notice that laser expenses are negligible since laser cutting is highly automated. Compared to the other cutting processes, the operating and machine expenses are minimal.

Due to the high cost of laser cutting machines, outsourcing the laser cutting part is the most effective choice. This cost can considerably be reduced due to less changeover because the laser does not become worn or dull. Therefore, the more orders you make, the more cost-effective the laser cutting process becomes for you.

Efficiency, automation, and speed that is unrivaled

Laser cutting provides a very high speed. The exact pace will vary depending on the tolerance of the parts and the complexity of the work. Laser cutters are generally run by CNC controls. The formulas of the work are entered into the program. This allows the fabricator to create every product similarly, resulting in fewer failures per batch.

Quality and precision

Laser cutting produces extremely small cuts with extremely tight tolerances. The more precision you want in your project, the slower the laser moves. Laser cutting is the only way to achieve fine engravings and cuttings. Beyond that, all the edges and curves generated by laser cutters are crisp, smooth, and clean, implying minimal warping since the laser easily melts the metal instead of physically cutting it. You must remember that if you have to cut thick metal sheets, the laser may leave some melted metal scum on the metal. Apart from this, in the case of laser cutting, there is little to no cleanup. If you are looking for an alternative, you should check out the UV flatbed printer supplier Malaysia.

Versatility

The laser cutting option is a wonderful alternative for any project of any size because of the automation, precision, speed, and cost. Industrial orders, large cutouts on prototypes, delicate designs, etc., can be made easier with the laser cutting option. Without stopping the creation process, the lasers can create slots, tabs, holes, and other fabrications. These tight tolerances can produce finely detailed designs with complete precision. This all is possible only because the laser is doing the job. If it is done manually or if it is done by any other fabrication method, you will not have such clean cuts and precise work. If you do not need precise tolerances, the laser can move even faster and manufacture parts at breakneck speeds. Therefore, laser cutting is the perfect solution for many projects.